|

|---|

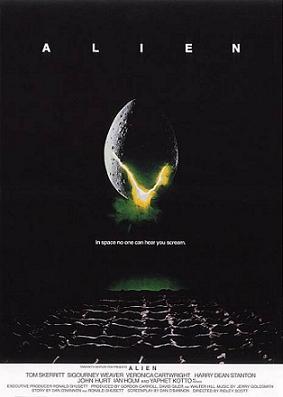

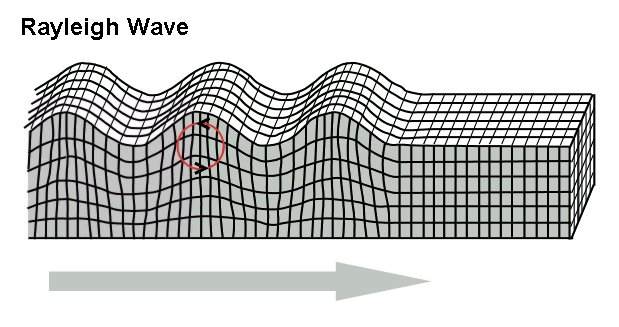

Mechanical waves require a medium to propagate. Sound waves can't propagate in the vacuum of space.

|

|

|---|---|

|

|

|

|

|---|---|---|---|

In rock, pressure waves propagate at ~ 5 km/s and shear waves propagate at ~ 3 km/s. You can estimate the distance from the center of an earthquake by measuring the time difference between the arrival of the pressure and shear waves.

|

|

|

|---|---|---|

|

|

|

|---|---|---|

|

|

|

|---|---|---|

|

|

|

|---|---|---|

|

|

|

|

|---|---|---|---|

|

|---|

The Young's modulus characterizes the stiffness of a wire and it is proportional

to the spring constant.

Toughness is a measure of the maximum energy density that a material can absorb

before breaking. A tough material must be both strong and flexible.

Piano strings are "tough" in the sense that they are designed to absorb a large

strain before breaking. The tradeoff is that they cannot hold an edge.

Wootz steel is a steel-carbon alloy designed to be both strong and flexible.

The following table shows the maximum strain of a material before breaking.

Toughness is a measure of the maximum energy density that a material can absorb

before breaking. A tough material must be both strong and flexible.

The maximum energy/mass of a spring is proportional to the toughness/density.

Concrete and ceramics typically have much higher compressive strengths than

tensile strengths. Composite materials, such as glass fiber epoxy matrix

composite, tend to have higher tensile strengths than compressive strengths.

The deformation of a solid is characterized by shear strain, tensile strain,

and bulk compression.

Tensile strength relates to the strength of wires.

Shear strength relates to the strength of beams and columns.

The maximum force on a beam is determined by the shear strength.

If a column is short then it squashes before it buckles and if it is long then

it buckles before it squashes.

A column's resistance to squashing is determined by the Bulk strength.

If a material can be compressed indefinitely (until it turns into a neutron

star) then it has no concept of a "bulk strength". This applies especially to

metals and diamonds. Hence, the "bulk modulus" is usually the only meaningful

variable for compression.

A wire shortens when stretched and widens when compressed.

For an isotropic material the tensile, shear, and bulk moduli are related

through the dimensionless Poisson ratio.

The following figure characterizes the relation between the shear and tensile moduli.

The relationship applies well for most metals.

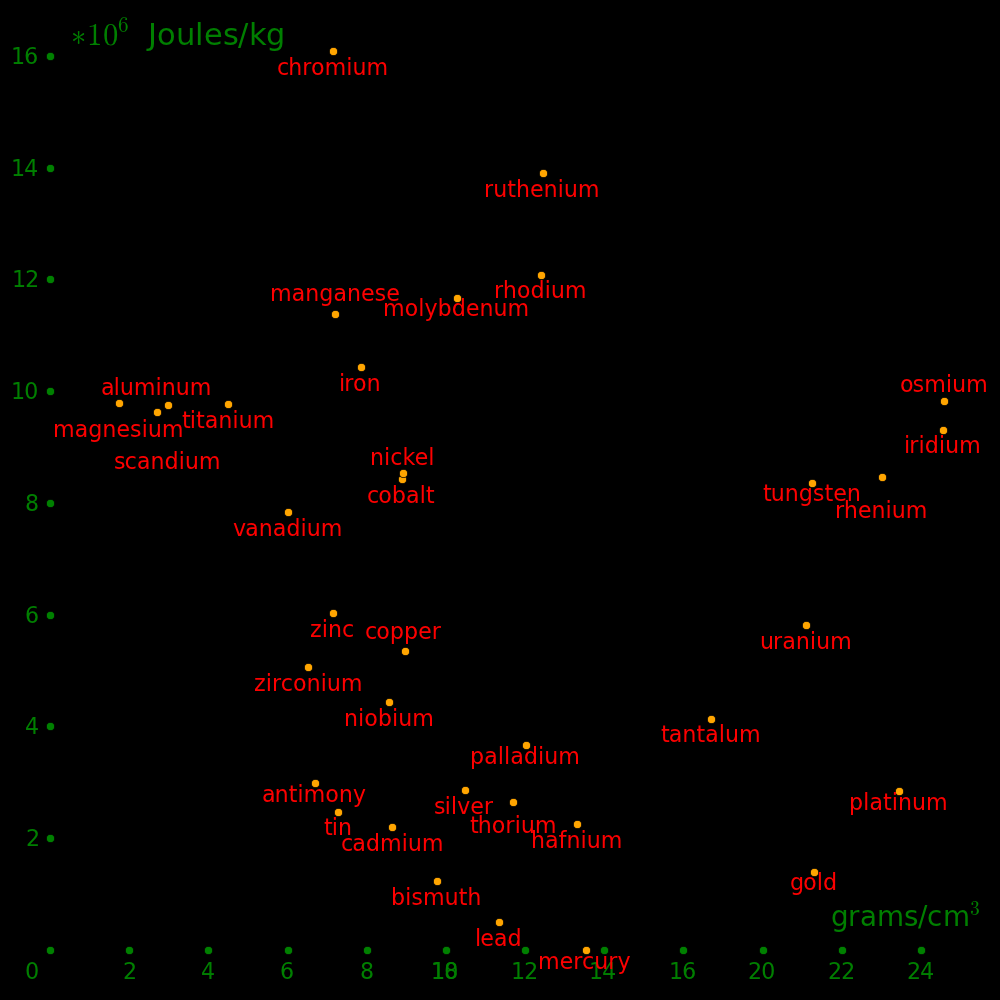

Previous to the discovery of tungsten, gold was an uncounterfeitable currency because

no material existed that was both more dense and less expensive than gold.

Osmium is the densest element and it is also expensive, making it useful as a currency.

Chromium is common in the Earth's crust and Ruthenium is rare.

For carbon, the values are given for diamond form.

Gold was the densest known element until the discovery of platinum in 1735.

This made it impossible to counterfeit as a currency.

Metals with a strength-to-weight ratio less than lead are not included, except

for mercury.

Corundum is a crystalline form of aluminium oxide (Al2O3). It is transparent in

its pure orm and can have different colors when metal impurities are

present. Specimens are called rubies if red, padparadscha if pink-orange, and

all other colors are called sapphire, e.g., "green sapphire" for a green

specimen.

Lignin comprises 30 percent of wood and it is the principal structural element.

A string ideally has both large strength and large strain, which favors

Vectran.

Below is a list of the elastic variables for a material, with examples for

large and small values for each variable.

Not all of of the above variables are independent. The toughness and

maximum strain are determined from the strength and modulus.

The most important variables for high-performance materials are

This table shows the elements with the highest melting points.

"Temperature" refers to the maximum temperature before the magnet loses its magnetism.

For a given instrument there is a characteristic ideal tension for the strings.

If the tension is too low or high the string becomes unplayable. The tension can

be varied to suit the performer's taste but it can't be changed by an extreme

degree.

The frequency of a string and the speed of a wave on the string are

related by:

The speed of a wave on a string is

The larger the radius the more difficult the string is to play and the more

impure the overtones. The radius can be minimized by using a material with a

high density. This is why cello, bass, and bass guitar strings are often made of

tungsten.

High-density strings are only appropriate for low-frequency strings because

they have a low wavespeed. High-frequency strings require a material with low

density.

String manufacturers almost never state the density and radius of the string.

You can infer the density from the type of metal used, with numbers given the

table below.

The speed of sound in air has an analogous form as the speed of a wave on a string.

If the tension force on a string exceeds the "Tensile strength" then the string

breaks.

A space elevator requires a material with Z > 100.

Gut was usually used in the Baroque age because steel alloys hadn't been

perfected. A-strings were tuned to a frequency of around 420 Hertz.

Modern steel made possible the 660 Hertz E-string and the high-frequency strings

on a piano.

You can use zylon to make a bass sound like a violin.

Tungsten is a high-density metal that can be used to make low-frequency strings

("Darth Vader" strings). You can make a violin sound like a bass.

The larger the diameter of a string the more difficult it is to play. Diameter

sets the lower limit of the frequency of a string.

If a string is made of tungsten with a density of 19.25 g/cm^3 then the

diameter of the lowest string on each instrument is

The "Tungsten" lines are string diameters for tungsten and the "Zylon" lines

are string diameters for zylon. Tungsten diameters assume a density of 19.3

g/cm^3 and zylon diameters assume a density of 1.5 g/cm^3. The zylon lines cut

off at the right at the frequency where the string breaks.

The price is for strings made of gold with a density 19.3 g/cm^3, the same

as for tungsten.

If the strings are made from iridium or osmium then the metal price is half this.

For tungsten strings the price of the tungsten is negligible.

Even though iridium is half the price of gold, gold wire may be cheaper because

gold is easier to forge.

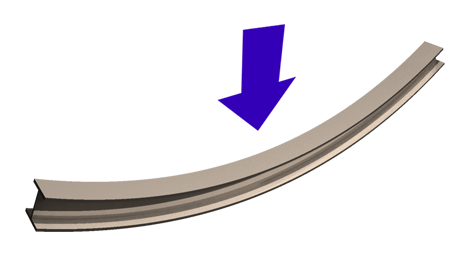

When a beam is bent it exerts a restoring force. If a string is too stiff it

acts like a beam and becomes impossible to play. The stiffness is inversely

proportional to the Young's modulus. This is why metal strings are usually

wound around a flexible core.

Examples of beam vibrations.

Strings typically have a flexible core with a low Young's modulus and a high-density

metallic winding.

The overtones of an ideal string are exact integer ratios.

If the string is non-ideal then the overtones can change.

The principal source of non-ideality is the finite thickness of the string.

String stiffness also contributes non-ideality.

Plucked strings exhibit inharmonicity. Bowed strings are "mode-locked" so that

the harmonics are exact integer ratios. Reed instruments and the human voice

are also mode locked.

The coefficient of inharmonicity can be expressed in terms of density as

Low strings are more inharmonic than high strings.

The higher the note you play on a string, the smaller the effective string length

and the more inharmonic the note. This is what prevents you from playing notes

of arbitrarily high frequency.

The following is a table of inharmonicity coefficients for various instruments.

We have assumed standard values for the string tension and we assume the string

has the density of steel.

The lower the frequency of a string, the more inharmonic it is. Low-frequency

strings typically consist of a synthetic core (for

elasticity) and an outer metallic winding (for density).

You can't use metal for the entire string because metal is too stiff (the Young's

modulus is too high.

An ideal core material has a high tensile strengh, so that you can use a small

core diameter, and a low Young's modulus, to minimize inharmonicity. The

synthetic material that is best suited for this is Vectran (see the table

above).

For constant string length the ideal force doesn't depend on frequency.

If "r" is too large compared to "R" then the string loses density. We assume that

r is is a fixed fraction of R and that r/R ~ 2/5.

Using

Let

The following table shows a set of example parameters for low-frequency strings.

We assume a core of Vectran (density=1400 kg/m^3) and a winding of

osmium (density=22600 kg/m^3).

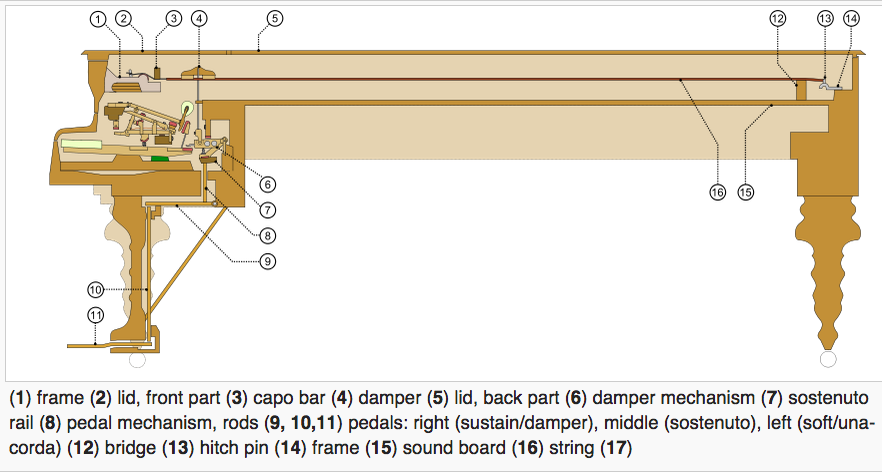

The strings in a piano exert a force of 20 tons.

The Sydney Town Hall Grand Organ has pipes that are 64 feet long, which

corresponds to a frequency of 8.5 Hertz.

Developed theories of eye focus, depth perception, color vision, and motion perception.

Invented the "Helmholtz resonator" for measuring the frequency spectrum of sound.

Discovered the shape of the oscillation of a violin string.

Demonstrated that different combinations of resonators could mimic vowel sounds.

Measured the speed of neurons.

Developed the principle of conservation of energy and demonstrated that it applies

to mechanics, heat, light, electricity and magnetism.

Demonstrated that muscle metabolism conserves energy.

Invented the field of psychology with his student Wilhelm Wundt.

In 1863, Helmholtz published "On the Sensations of Tone", which became the standard

reference for the next century.

Students: Max Planck, Heinrich Kayser, Eugen Goldstein, Wilhelm Wien, Arthur

Konig, Henry Augustus Rowland, Albert A. Michelson, Wilhelm Wundt, Fernando

Sanford and Michael I. Pupin.

Amati (1505-1577) lived in Cremona, Italy, and developed the first violins, violas,

and cellos.

A gas molecule moving in 3 dimensions has 3 degrees of freedom and so the

mean kinetic energy is

The speed of sound is

Using the ideal gas law,

If we express the ideal gas law in terms of density,

We can change the sound speed by using a gas with a different value of M.

The fact that Newton's calculation differed from the measured speed is due to

the fact that air consists of diatomic molecules (nitrogen and oxygen). This

was the first solid clue for the existence of atoms, and it also contained a

clue for quantum mechanics.

In Newton's time it was not known that changing the volume of a gas changes its

temperature, which modifies the relationship between density and pressure.

This was discovered by Charles in 1802 (Charles' law).

For a diatomic gas there are also two rotational degrees of freedom. In this

case d=5.

In general,

The fact that Gamma=7/5 for air was a clue for the existence of both atoms,

molecules, and quantum mechanics.

For dark energy,

As a substance expands it does work on its surroundings according to its pressure.

Dark matter consists of pointlike particles but they rarely interact with other

particles and so they exert no pressure.

Wave type Wave speed squared

Sound in air 1.4 * Pressure / Density

String wave Tension / (Density * CrossSectionalArea)

Longitudinal wave BulkModulus / Densty

Shear wave ShearModulus / Density

Torsion wave ShearModulus / Density

Deep water wave GravityConstant * Wavelength / (2 Pi) (If Depth > .5 Wavelength)

hallow water wave GravityConstant * Depth (If Depth < .5 Wavelength)

GravityConstant = 9.8 meters/second^2

If the wave speed doesn't depend on the frequency then waves propagate without

changing shape (without dispersion). This applies to all waves except for deep

water waves.

Bulk Density Sound speed

modulus (g/cm^3) (km/s)

(GPa)

Air .00014 .0012 .34

Water 2.2 1.0 1.43

Wood 13 1 3.6

Granite 100 2.75 6.0

Steel 170 7.9 6.1

Diamond 443 3.5 12.0

Beryllium 130 1.85 12.9 Fastest sound speed of any material

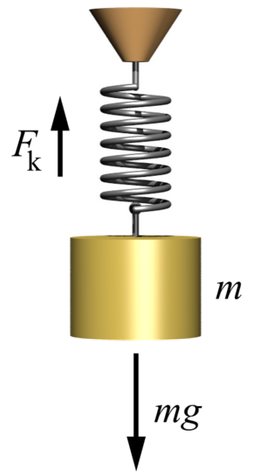

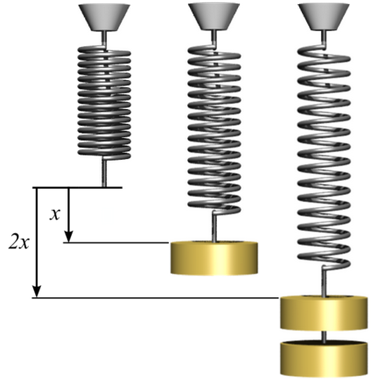

x = Displacement of the spring when a force is applied

K = Spring constant

Force = Force on the spring

= K x (Hooke's law)

Force = Tension force on the wire

X = Length of wire under zero tension force

x = Increase in length of the wire when a tension force is applied

Area = Cross-sectional area of the wire

Stress= Force / Area (Pressure, measured in Pascals or Newtons/meter^2)

Strain= Fractional change in length of the wire

= x/X

Young = Tensile modulus or "Young's modulus" for the (Pascals)

Hooke's law in terms of stress and strain is

Stress = Young * Strain

Young = K X / Area

If the Young's modulus of a string is too high it is too stiff to play.

This is why the core of a string is often made from an elastic material such

as nylon or gut.

Tensile yield strength = Maximum stress before the material irreversibly deforms

Tensile strength = Maximum stress before the material breaks

Density = Density of the wire

Stress = Force/Area on the wire

Strain = Fractional change in length of the wire

StressMax= Maximum stress before breaking

= Tensile strength

StrainMax= Tensile strain strength. Maximum strain before breaking

Young = Young's modulus

= Stress/Strain

Yield = Yield modulus

= Stress for which the material irreversibly deforms

Toughness= Energy/volume in the wire when at maximum stress

= .5 * StressMax^2 / Young

U = Toughness/Density

= Energy/kg in the wire when at maximum stress

Stress = Young * Strain

StressMax = Young * StrainMax

Toughness = .5 * Young * StrainMax^2

= .5 * StressMax^2 / Young

The ability of a material to keep an edge is related to its Young's modulus

and tensile strength.

Density = Density of the wire

Stress = Force/Area on the wire

Strain = Fractional change in length of the wire

StressMax= Maximum stress before breaking

= Tensile strength

StrainMax= Tensile strain strength. Maximum strain before breaking

Young = Young's modulus

= Stress/Strain

Yield = Yield modulus

= Stress for which the material irreversibly deforms

Toughness= Energy/volume in the wire when at maximum stress

= .5 * StressMax^2 / Young

U = Toughness/Density

= Energy/kg in the wire when at maximum stress

Stress = Young * Strain

StressMax = Young * StrainMax

Toughness = .5 * Young * StrainMax^2

= .5 * StressMax^2 / Young

The ability of a material to keep an edge is related to its Young's modulus

and tensile strength.

Young's Yield Tensile Tensile Tough Tough/ Brinell Density Poisson

modulus strengh strain density (GPa) (g/cm^3)

(GPa) (Gpa) (GPa) (MPa) (J/kg)

Beryllium 287 .345 .448 .0016 .350 189 .6 1.85 .032

Magnesium 45 .100 .232 .0052 .598 344 .26 1.74 .29

Aluminum 70 .020 .050 .00071 .018 15 .245 2.70 .35

Titanium 120 .225 .37 .0031 .570 54 .72 4.51 .32

Chromium 279 .282 .00101 .143 199 1.12 7.15 .21

Iron 211 .100 .35 .0017 .290 37 .49 7.87 .29

Cobalt 209 .485 .760 .0036 1.382 155 .7 8.90 .31

Nickel 170 .190 .195 .0011 .112 12.5 .7 8.91 .31

Copper 130 .117 .210 .0016 .170 19 .87 8.96 .34

Molybdenum 330 .324 .00098 .159 15 1.5 10.28 .31

Silver 83 .170 .0020 .174 17 .024 10.49 .37

Tin 47 .014 .200 .0043 .426 59 .005 7.26 .36

Tungsten 441 .947 1.51 .0037 2.585 134 2.57 19.25 .28

Rhenium 483 .290 1.07 .0024 1.298 62 1.32 21.02 .30

Osmium 590 1.00 .0018 .893 40 3.92 22.59 .25

Iridium 528 2.0 .0038 3.788 168 1.67 22.56 .26

Platinum 168 .165 .00098 .081 3.8 .32 21.45 .38

Gold 78 .127 .0016 .103 5.3 .24 19.30 .44

Lead 16 .012 .00075 .045 3.8 .44 11.34 .44

Al Alloy 70 .414 .483 .0069 1.666 595 2.8

Brass 125 .20 .55 .0044 1.210 139 8.73

Bronze 120 .800 .0067 2.667 300 8.9

Steel 250 .250 .55 .0022 .605 77 7.9 .30

Stainless 250 .52 .86 .0034 1.479 185 8.0 .30

W-C 650 .345 .00053 .092 5.9 15.63

Si-C 450 - 3.44 .0076 13.10 4100 3.21

Rubber .1 .016 .5

Nylon 3 .045 .075 .025 .938 815 1.15

Carbon fiber 181 1.600 .0088 7.07 4040 1.75

Kevlar 100 3.62 3.76

Zylon 180 2.70 5.80 1.56

Colossal tube - 7 .116 Carbon colossal nanotube

Nanorope ~1000 - 3.6 .0036 6.5 4980 1.3 Rope made from nanotubes

Nanotube 1000 - 63 .063 1980 1480000 1.34 Carbon nanotube

Graphene 1050 - 160 .152 12190 12190000 1.0

Carbyne 32100 Unstable

Air 0 0 0 0 0 0 .0012

Water 0 0 0 0 0 0 1.00

Ice .001 .33

Cork low 0

Glass 45 .033 2.53 .25

Concrete 30 .005 2.7 .2

Granite 70 .025 2.7 .2

Basalt .030

Marble 70 .015 2.6 .2

Skin .015 .020 2.2

Bone 14 .120 .130 .0093 604 377 1.6

Balsa

Pine .04

Oak 11

Bamboo .50 .4

Ironwood 21 .181 .0086 780 650 1.2

Tooth enamel 83

Human hair .380

Spider silk 1.0 1.3

Sapphire 345 .4 1.9 .0055 5232 1315 3.98 .28

Diamond 1220 1.6 2.8 .0023 3210 920 1200 3.5 .069

Young's Yield Tensile Tensile Tough Tough/ Brinell Density Poisson

modulus strengh strain density (GPa) (g/cm^3)

(GPa) (Gpa) (GPa) (kPa) (J/kg)

The listed strain is for when the material is at the breaking point.

Energy/mass

(MJ/kg)

Fission 69500000

Diesel fuel 47

Lithium battery .95

Supercapacitor .018

Spring .0003

F = Maximum force applied to the center of a beam before it breaks

X = Beam length

Y = Beam thickness

Z = Beam height

x = Deflection of the beam at the center when under force "F"

ShearStrength = 3 F X / (2 Y Z^2)

A = Area of the column

B = Bulk strength of the column

F = Force required to squash a column

= B A

A column's resistance to buckling is determined by the Young's modulus.

Suppose a column is a hollow cylinder.

L = Length of the column

R = Outer radius of the column

r = Inner radius of the column (r=0 if the cylinder is not hollow)

Y = Young's modulus

Q = Dimensionless effective length of the column

= .5 if both ends are fixed

= 2 if one end is fixed and the other end is free to move laterally

= 1 if both ends are pinned (hinged and free to rotate)

= .699 if one end is fixed and the other is pinned

F = Force required to buckle the column

F = .5 Pi Y (R-r) / (Q L)

If a column's buckling limit is equal to its squashing limit then (assume r=0)

R/L = (Q/Pi) * (2B/Y)

Z = Height of a beam

X = Length of a beam

Y = Width of a beam

Area = Surface area of the top face of the beam

= X Y

Force = Transverse force on the top face of the beam in the X direction

x = Transverse displacement of the top face of the beam when a transvere

force is applied

ShearStress = Force / (X Y)

Shearstrain = x/Y

ShearModulus = ShearStress / ShearStrain

ShearYield = Shear stress for which the material deforms irreversibly

ShearStrength = Maximum shear stress before breaking

ShearStrainMax= Maximum strain before breaking

ShearToughness= Energy/Volume absorbed by the material when at maximum strain

= .5 ShearModulus * ShearStrainMaax^2

= .5 ShearStrength^2 / ShearModulus

ShearStress = ShearModulus * ShearStrain

ShearStrength = ShearModulus * ShearStrainMax

Tensile strain and shear strain have analogous elastic variables.

TensileStress <--> ShearStress

Tensilestrain <--> Shearstrain

Tensilemodulus <--> ShearModulus

TensileYield <--> ShearYield

TensileStrength <--> ShearStrength

TensileStrainMax <--> ShearStrainMax

TensileToughness <--> ShearToughness

The bulk modulus is analogous to the tensile modulus and the strain modulus.

dX = Fractional increase in length of the wire

dY = Fractional decrease in diameter of the wire

PoissonRatio = dY / dX

2 * (1 + PoissonRatio) * ShearModulus = TensileModulus

3 * (1 - 2*PoissonRatio) * BulkModulus = TensileModulus

The Poisson ratio for most metals is in the range of 1/3 and for rubber it is 1/2.

If we assume the Poisson ratio is 1/3 then

(8/3) * ShearModulus = TensileModulus

Materials based on carbon chains differ from isotropic materials

in that they tend to have a large tensile strength and a low shear strength.

These materials are good for wires.

Vertical axis = ShearModulus

Horizontal axis = TensileModulus / (2 + 2*PoissonRatio)

.png)

Brinell = A measure of a material's resistance to dents, measured in Pascals

Mohs = A dimensionless measure of a material's resistance to dents

The Mohs scale of mineral hardness reflect's a material's ability to resist scratching.

If two materials are scraped together then the material with the lower Mohs value will

be scratched more. Diamond has the largest Mohs value of any material.

Mohs

Diamond 10

RhB2 9.5

Silicon carbide 9.5

Corundum 9

Tungsten carbide 9

Chromium 8.5

Emerald 8

Topaz 8

Tungsten 8

Hardened steel 8

Quartz 7

Osmium 7

Rhenium 7

Vanadium 7

If a material has a large Brinell hardness then it has a large Mohs hardness.

The reverse is not necessarily true. Materials exist with a large Mohs hardness

and a small Brinell hardness.

The Brinell hardness is related to the tensile modulus and tensile strength.

Vickers Tensile Tensile Tensile Tensile Poisson

hardness modulus strength tough strain

(GPa) (GPa) (GPa) (kPa) (GPa)

Hardened steel .8 250 .55 .29

Osmium 590 1.00 893 .25

Cobalt 1.04 209 .76 .31

Chromium 1.06 279 .282 143 .00101 .21

Tantalum 1.2 186 .90 .34

Beryllium 1.67 287 .448 .032

Iridium 2.2 528 2.0 3788 .0038 .26

Sapphire 2.3 345 1.9 5232 .0055 .28

Uranium 2.5 208 .625 .23

Si-C 2.6 450 3.44 13100 .0076 .19

W-C 2.6 650 .345 92 .00053 .23

Molybdenum 2.74 330 .324 159 .00098 .31

Ti-N 3.0 .25

Ti-C 3.2 439 .119 .19

Titanium 3.42 120 .37 570 .0031 .32

Tungsten 4.6 441 1.51 2585 .0037 .28

Boron 4.9 400 3.1

BN 6.0 100 .083 .27

Rhenium 7.58 483 1.07 1298 .0024 .30

Rhodium 8.0 275 .951 .26

Diamond 10.0 1220 2.8 3210 .0023 .069

All hard materials have a small Poisson ratio.

Density Price

(g/cm^3) ($/g)

Water 1.0

Nylon 1.2

Gut 1.5

Synthetic 2.5

Aluminum 2.8 <.01

Titanium 4.5 .01

Steel 7.9 <.01

Nickel 8.9 .01

Silver 10.5 .6

Tungsten 19.2 .05

Gold 19.3 24

Rhenium 21.0 6

Platinum 21.4 88

Iridium 22.56 13

Osmium 22.59 12 Densest element

Tungsten is the only dense metal that is not expensive.

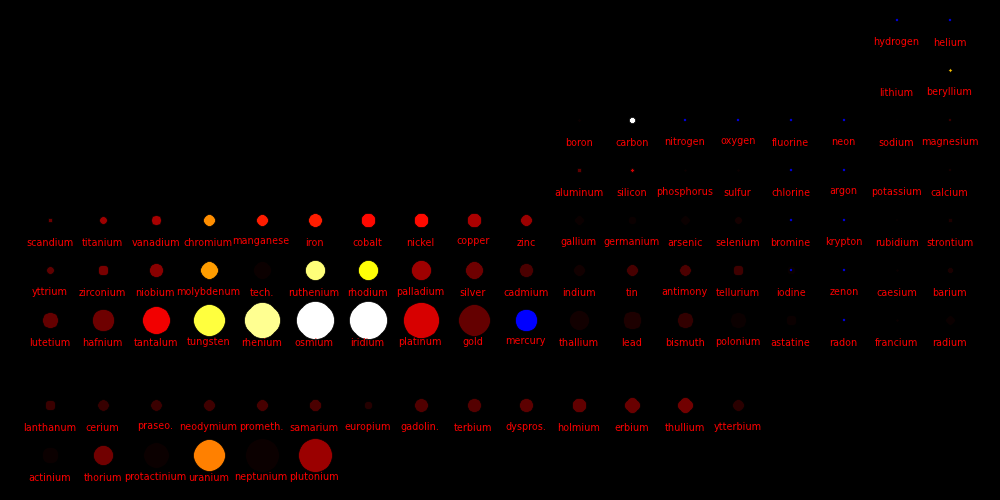

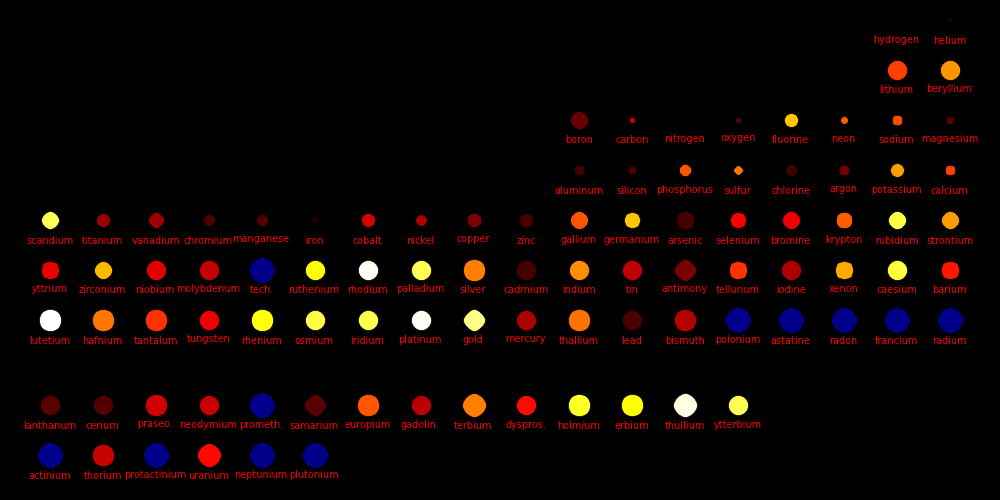

Color = Shear Modulus. Red is low, orange is medium, and white is high.

Dot size = Density

Shear data

Density data

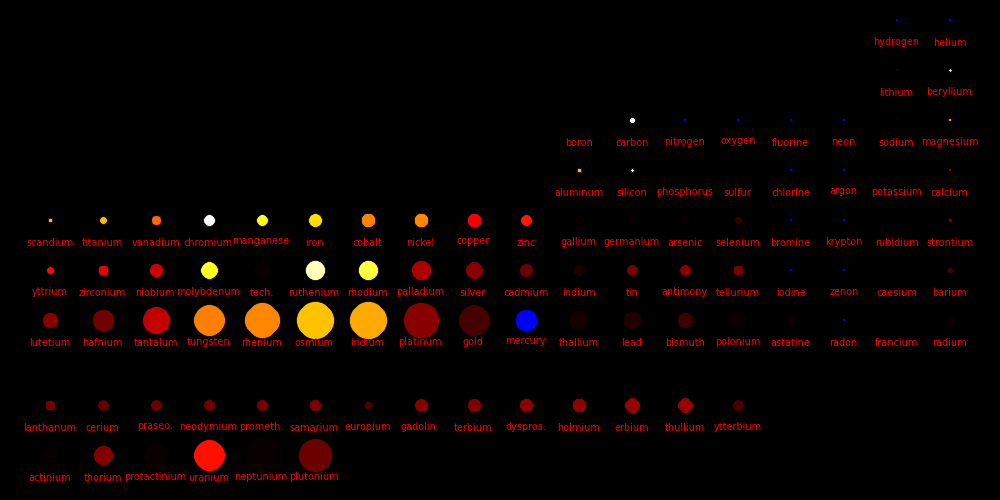

Color = Shear Modulus / Density A measure of a material's "strength to weight" ratio

Dot size = Density

The metals with the highest strength to weight ratio are Chromium, Ruthenium, and

Beryllium.

Dot size = (Shear Modulus)^(1/3) An indicator of a material's strength

Dot color = Melting point

White = Highest melting points

Red = Lowest melting points

Blue = Elements that are a gas or a liquid at room temperature and pressure.

Liquids and gases have a shear modulus of 0.

Rocket cones are made from materials with a high melting point, a high shear

strength, and a high atomic mass. Tungsten is the element of choice,

especially because it's vastly cheaper than Rhenium, Osmium, and Iridium.

Color = Price per kilogram Red is low, orange is medium, white is high

Blue indicates the element is radioactive with a

short half life

Dot size = -log(SolarAbundance) The smaller the dot, the more abundant the element

Price data

Dot size = Atomic radius

= (AtomicMass / Density)**(1/3)

For gases, the density at boiling point is used.

Dot size = [Shear modulus / Density]**(1/2)

Color = Poisson ratio, ranging from red to white

Dot size = [Brinell hardness / Density]**(1/2)

Color = Poisson ratio, ranging from red to white

Brinell hardness is difficult to define for diamond, although it is substantially

larger than that for any other element. A nominal value is used in the table only

to indicate that it is large.

Earliest Shear Melt Density

known use Strength (K) (g/cm^3)

(year) (GPa)

Wood < -10000 15 - .9

Rock < -10000

Carbon < -10000

Diamond < -10000 534 3800 3.5

Gold < -10000 27 1337 19.3

Silver < -10000 30 1235 10.5

Sulfur < -10000

Copper -9000 48 1358 9.0

Lead -6400 6 601 11.3

Brass -5000 ~40 Copper + Zinc

Bronze -3500 ~40 Copper + Tin

Tin -3000 18 505 7.3

Antimony -3000 20 904 6.7

Mercury -2000 0 234 13.5

Iron -1200 82 1811 7.9

Arsenic 1649 8 1090 5.7

Cobalt 1735 75 1768 8.9 First metal discovered since iron

Platinum 1735 61 2041 21.4

Zinc 1746 43 693 7.2

Tungsten 1783 161 3695 19.2

Chromium 1798 115 2180 7.2

Stone age antiquity

Copper age -9000

Bronze age -3500

Iron age -1200

Bronze holds an edge better than copper and it is more corrosion resistant.

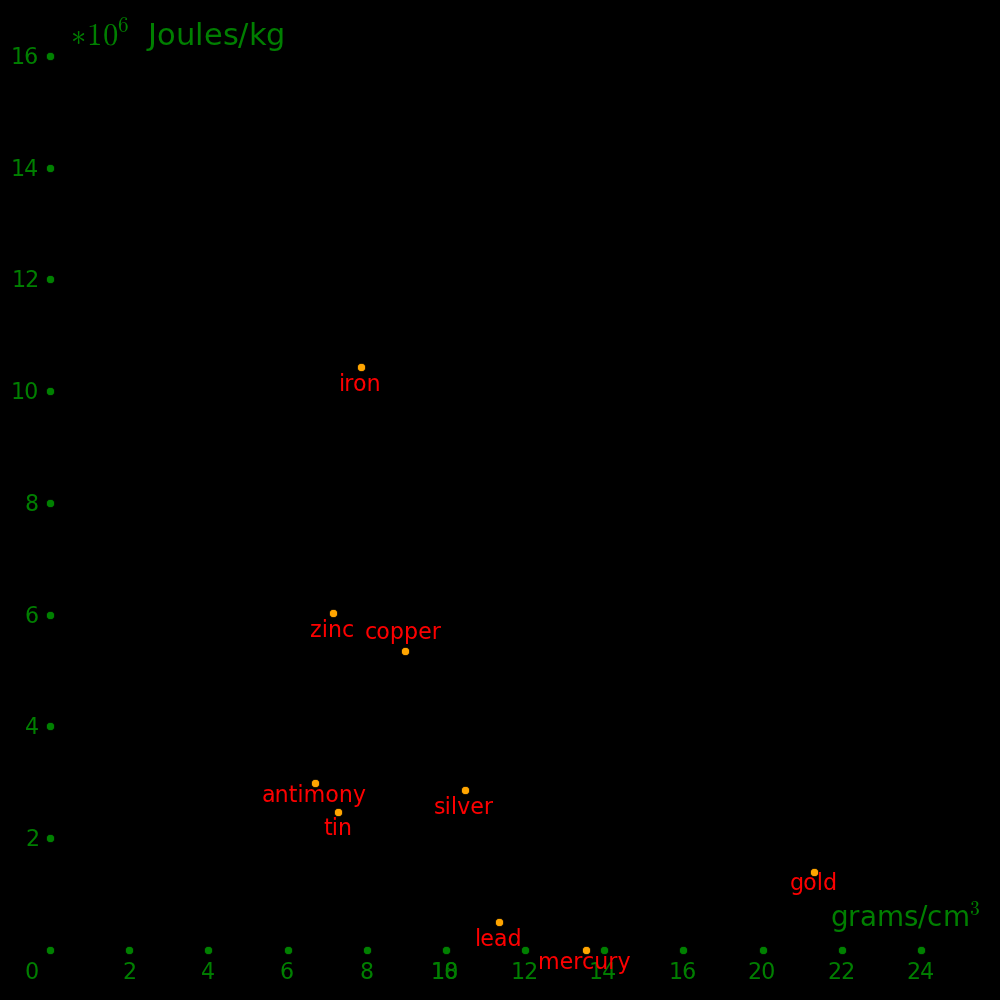

Horizontal axis: Density

Vertical axis: Shear modulus / Density (Strength-to-weight ratio)

Horizontal axis: Density

Vertical axis: Shear modulus / Density (Strength-to-weight ratio)

Beryllium is beyond the top of the plot.

.jpg)

Metal impurity Color

Chromium Red

Iron Blue

Titanium Yellow

Copper Orange

Magnesium Green

.gif)

Year Young Tensile Strain Density Common

(GPa) strength (g/cm^3) name

(GPa)

Gut .2

Cotton Ancient .1 1.5

Hemp Ancient 10 .3 .023

Polyamide 1939 5 1.0 .2 1.14 Nylon, Perlon

Polyester 1941 15 1.0 .067 1.38

Polypropylene 1957 .91

Polyethylene 1939 117 1.4 Dacron

Carbon fiber 1968 3.0 1.75

Aramid 1973 135 3.0 .022 1.43 Kevlar

HMPE 1975 100 2.4 .024 .97 Dyneema, Spectra

LCAP 1990 65 3.8 .058 1.4 Vectran

Vectran HT 75 3.2 .043 1.41 Vectran

Vectran NT 52 1.1 .021 1.41 Vectran

Vectran UM 103 3.0 .029 1.41 Vectan

PBO 1985 280 5.8 .021 1.52 Zylon

Nanorope ~1000 3.6 .0036 1.3

Nanotube 1000 63 .063 1.34

Graphene 1050 160 .152 1.0

Strain = Strength / Young

Carbon fiber is not useful as a rope.

Small value Large value

Tensile modulus Climbing rope Bicycle spokes

Tensile yield

Tensile strength Violin strings

Tensile max strain Climbing rope

Tensile toughness Elevator cable

Shear modulus Golf driver Bike frame

Shear yield Spring

Shear strength Beam

Shear toughness Sword interior

Shear max strain Golf driver

Bulk modulus Pillow

Brinell hardness Machining metal Sword edge

Mohr hardness Pencil lead Cutting tools

Poisson ratio

Density Airplane frame Bullet

Some examples of materials used for high-performance applications are

Rocket cones Tungsten

Wire Zylon, Sapphire, Carbon nanorope

Sword inerior Aluminum alloy, Sapphire

Sword edge Diamond

Clock escapement Diamond, Tungsten carbide

Formula-1 brakes Carbon

Bullet Lead, Tungsten, Uranium, Osmium

Lubricants Fullerines

Brass is a useful machining metal because it is easy to cut.

Example

Tensile strength Maximum stress on a wire

Shear modulus Stiffness of a beam or column

Shear strength Maximum stress on a beam or column

Brinell hardness Sword edge

Mohr hardness Cutting tools

Density Bullets

Below is a table of the stoutest engineering materials.

Young's Yield Tensile Tensile Tough Tough/ Brinell Density Poisson

modulus strengh strain density (GPa) (g/cm^3)

(GPa) (Gpa) (GPa) (MPa) (J/kg)

Beryllium 287 .345 .448 .0016 .350 189 .6 1.85 .032

Mg alloy 45 .100 .232 .0052 .598 344 .26 1.74 .29

Al alloy 70 .414 .483 .0069 1.666 595 .245 2.8 .35

Titanium 120 .225 .37 .0031 .570 54 .72 4.51 .32

Chromium 279 .282 .00101 .143 199 1.12 7.15 .21

Iron 211 .100 .35 .0017 .290 37 .49 7.87 .29

Cobalt 209 .485 .760 .0036 1.382 155 .7 8.90 .31

Nickel 170 .190 .195 .0011 .112 12.5 .7 8.91 .31

Copper 130 .117 .210 .0016 .170 19 .87 8.96 .34

Molybdenum 330 .324 .00098 .159 15 1.5 10.28 .31

Tin 47 .014 .200 .0043 .426 59 .005 7.26 .36

Tungsten 441 .947 1.51 .0037 2.585 134 2.57 19.25 .28

Rhenium 483 .290 1.07 .0024 1.298 62 1.32 21.02 .30

Osmium 590 1.00 .0018 .893 40 3.92 22.59 .25

Iridium 528 2.0 .0038 3.788 168 1.67 22.56 .26

Brass 125 .20 .55 .0044 1.210 139 8.73

Bronze 120 .800 .0067 2.667 300 8.9

Steel 250 .250 .55 .0022 .605 77 7.9 .30

Stainless 250 .52 .86 .0034 1.479 185 8.0 .30

W-C 650 .345 .00053 .092 5.9 15.63

Si-C 450 - 3.44 .0076 13.100 4100 3.21

Carbon fiber 181 1.600 .0088 7.070 4040 1.75

Kevlar 3.62 3.76

Zylon 180 2.70 5.80 1.56

Nanorope ~1000 - 3.6 .0036 6.5 4980 1.3 Rope made from nanotubes

Nanotube 1000 - 63 .063 1980 1480000 1.34 Carbon nanotube

Graphene 1050 - 160 .152 12190 12190000 1.0

ColossalTube low - 7 .116

Balsa

Bamboo .500 .4

Ironwood 21 .181 .0086 .780 650 1.2

Sapphire 345 .4 1.9 .0055 5.232 1315 3.98 .28

Diamond 1220 1.6 2.8 .0023 3.210 920 1200 3.5 .069

Young's Yield Tensile Tensile Tough Tough/ Brinell Density Poisson

modulus strengh strain density (GPa) (g/cm^3)

(GPa) (Gpa) (GPa) (kPa) (J/kg)

Element Density Melt Boil Young Young/ $/kg ppm in metallic

(g/cm^3) (K) (K) GPa Density asteroid

Tungsten 19.25 3693 5828 411 21.4 50 ~ 1

Rhenium 21.0 3459 5869 463 22.0 4600 ~ 1

Osmium 22.59 3306 5285 550 24.3 12000 2

Tantalum 16.7 3290 5731 186 11.1 400 ~ .5

Molybdenum 10.28 2896 4912 329 31.0 21 ~10

Niobium 8.75 2750 5017 105 12.0 40 ~ 3

Iridium 22.4 2739 4701 528 23.6 14000 2

Ruthenium 12.45 2607 4423 447 35.9 5500 5

Composition Teslas kJoules/ kAmps/ Max Density Tensile

meter^3 meter Temperature (g/cm^3) strength

(C) (GPa)

Neodymium Nd2Fe14B 1.4 440 2000 400 7.4 .075

Samarium-Cobalt SmCo5 1.15 240 1300 800 8.3 .035

Alnico 1.4 88 275 860

The composition of alnico alloys is typically 8-12% Al, 15-26% Ni, 5-24% Co, up to

6% Cu, up to 1% Ti, and the balance is Fe.

String Height of Height of

length Tension (Newtons) top string bottom string

(mm) E A D G C (mm) (mm)

Violin 320 80 50 45 45 3.2 5.2

Viola 388 65 55 55 55 4.8 6.2

Cello 690 160 130 130 130 5.2 8.2

Bass 1060 160 160 160 160

Guitar 650 120 120 120 120

Bass guitar 860 160 160 160 160

The height of the string is the distance from the fingerboard.

Values for a violin A-string

L = Length of a string = .32 meters

F = Vibration frequency of the string = 440 Hertz

V = Speed of a wave on the string = 281.6 meters/second

= 2 F L

For a given instrument and string frequency, the wavespeed is fixed.

WaveSpeed^2 = Tension / (Density * Pi * Radius^2)

The variables you can vary for a string are {Tension, Density, Radius}.

Once you have chosen the frequency and length of the string then these variables

are related by

Tension = Constant * Density * Radius^2

SoundSpeed^2 = (7/5) Pressure / Density

Force = Force on the string

A = Area of the string

S = Stress on the string

= Force / A

Smax = Tensile strength

= Maximum string stress before breaking

Z = Strength to weight ratio

Z = Smax / Density

Tensile Density Z/10^6 Young's

strength modulus

(GPa) (g/cm^3) (J/kg) (GPa)

Carbon nanotube 7 .116 60.3 Technology not yet developed

Nylon .045 1.15 .04 5

Kevlar 3.6 1.44 2.5

Zylon 5.8 1.5 3.9

Gut .2 1.5 .13 6

Magnesium alloy .4 1.8 .22

Aluminum .05 2.7

Titanium alloy .94 4.5 .21

Nickel .20 8.9

Chromium .28 7.2

Steel alloy 2.0 7.9 .25 220

Brass .55 8.7

Silver .17 10.5

Tungsten .55 19.2 .029

Gold .13 19.3

Osmium 1.0 22.6

Iridium

F = String frequency

R = String radius

A = String cross-sectional area

= Pi R^2

D = String density

L = String length

Force= String tension force (Newtons)

S = Tensile stress (Pascals)

= Force / A

Smax = Maximum string tensile stress before breaking

= Tensile strength

V = Speed of a wave on the string

= SquareRoot(P/D)

Z = String strength-to-weight ratio

= S/D

Fmax = Maximum frequency of a string

The maximum frequency of a string happens when S=Smax.

Fmax = V / (2L)

= SquareRoot(Smax/D) / (2L)

= SquareRoot(Z) / (2L)

The maximum frequency of a string depends on the strength-to-weight ratio Z.

Values for Z for various string materials are given in the table above.

Steel alloy is often used for the highest-frequency strings on a violin or

piano.

Gut Steel Zylon Carbon Tungsten

nanotube

Violin 563 781 2960 12100 266

Viola 465 644 2440 3160 220

Cello 261 362 1370 5620 123

Bass 170 236 895 3660 80

Guitar 277 385 1519 5973 131

Bass guitar 209 291 1148 4514 99

Frequencies are in Hertz.

Frequency = Constant * SquareRoot(Smax/D) / R

String frequency is inversely proportional to radius. A string can be made an

octave lower by doubling the radius.

-

Freq Length Diameter

(Hz) (mm) (mm)

Violin G 196 320 .46

Viola C 130 388 .62

Cello C 65 690 1.07

Bass E 41 1060 1.18

Guitar E 82 650 .90

Bass guitar E 41 860 1.7

Density Price

(g/cm^3) ($/g)

Zylon 1.5 Cheap

Tungsten 19.2 .05

Gold 19.3 40

Rhenium 21.0 10

Platinum 21.4 80

Iridium 22.4 20

Osmium 22.6 20

R = String radius

L = String length

D = String density

Y = Young's modulus for the string

Force= Tension force on the string

N = An integer greater than or equal to 1

Fn = Frequency of overtone N

= N F (1 + C N^2)

C = Constant of inharmonicity

= Pi^3 R^4 Y / (8 L^2 Force)

If C=0 then there is no inharmonicity and the overtones are exact integer multiples

of the fundamental mode. If the string has finite thickness then the frequencies

of the overtones shift.

C = Pi Force Y / (128 D^2 F^4 L^6)

Increasing the density decreases the inharmonicity.

String Tension Frequency Density Radius Young's C

length (Newtons) (Hertz) (g/cm^3) (mm) modulus

(mm) (GPa)

Violin E gut 320 80 660 1.5 .31 6 .000026

Violin E steel 320 80 660 7.9 .13 220 .000033

Violin G steel 320 45 196 7.9 .34 220 .00012

Viola C steel 388 55 130 7.9 .47 220 .00019

Cello C steel 690 130 65 7.9 .81 220 .000098

Bass E steel 1060 160 41 7.9 .92 220 .000047

Guitar E steel 650 140 82 7.9 .70 220 .000058

Bass guitar E 860 220 41 7.9 1.34 220 .00017

If we set the frequency shift from inharmonicity equal to the frequency resolution

for human hearing,

N^2 C = 1/170

If C=.0001 then N=7.7 (The inharmonicity appears at the 8th overtone)

L = Length of the string

R = Outer radius of the string

r = Radius of the inner core

= K R where K is a dimensionless constant

Y = Young's modulus of the core material

D = Density of the outer winding

Force= Force on the string

= k L where k is a constant

Y = Young's modulus of the core

S = Stress on the inner core

= Force / (Pi r^2)

s = Strain on the inner core

= S/Y

C = Constant of inharmonicity

= Pi^3 R^4 Y / (8 L^2 Force)

= Pi Force Y / (128 D^2 F^4 L^6)

The strain should be as large as possible to minimize the Young's modulus, but

if it is too large then the string loses functionality. We assume that the

strain is a constant value.

Force / (Pi r^2) = Y s

The larger the value of "r" the lower the value of "Y" and the lower the inharmonicity.

Force = Pi R^2 4 D F^2 L^2

= Pi r^2 Y s

We have

4 D F^2 L^2 = K^2 Y s

The inharmonicity is

C = Pi Force Y / (128 D^2 F^4 L^6)

= Pi Force 4 D F^2 L^2 / (128 K^2 s D^2 F^4 L^6)

= Pi Force / (32 K^2 D F^2 s L^4)

= Constant * Force / (F^2 L^4)

If we assume that

Force = Constant * L

then

C = Constant / (F^2 L^3)

The lowest practical frequency of an instrument scales as L^(-3/2).

Relative inharmonicity = 1/(Freq^2 Length^3)

The relative inharmonicity of the lowest string for various instruments is

given by the following table. The value is similar for all instruments.

Freq Length Relative inharmonicity

(Hz) (mm) = 1/(Freq^2 Length^3)

Violin G 196 320 .00079

Viola C 130 388 .00101

Cello C 65 690 .00072

Bass E 41 1060 .00050

Guitar E 82 650 .00054

Bass guitar E 41 860 .00094

Note Freq Tension Core Core Outer Core Core

(Hertz) stress radius radius Young strain

(N) (GPa) (mm) (GPa)

Viola C 130.4 50 .2 .28 .70 70 .0155

Viola C 65.2 50 .2 .28 1.30 70 .0155

Viola C 65.2 50 1.0 .126 1.25 70 .0155

500 - 1400 Medieval

1400 - 1600 Renaissance

1600 - 1760 Baroque Monteverdi, Vivaldi, Bach, Handel

1720 - 1770 Galant Gluck

1730 - 1820 Classical Mozart

1780 - 1910 Romantic Beethoven, Brahms, Wagner

1890 - Now Modern Prokofiev, Shostakovich

1567 1643 Monteverdi

1637 1707 Buxtehude

1653 1706 Pachelbel

1659 1695 Purcell

1663 1713 Corelli

1671 1751 Albinoni

1678 1741 Vivaldi

1681 1767 Telemann

1685 1750 Bach

1685 1759 Handel

1732 1809 Haydn

1756 1791 Mozart

1770 1827 Beethoven

1782 1840 Paganini

1797 1828 Schubert

1803 1869 Berlioz

1809 1847 Mendelssohn

1810 1849 Chopin

1810 1856 Schumann

1813 1883 Wagner

1813 1901 Verdi

1833 1897 Brahms

1835 1921 Saint-Saens

1838 1920 Bruch

1840 1893 Tchaikovsky

1841 1904 Dvorak

1858 1924 Puccini

1860 1911 Mahler

1862 1918 Debussy

1864 1949 Strauss

1865 1957 Sibelius

1891 1953 Prokofiev

1906 1975 Shostakovich

1873 1943 Rachmaninov

1882 1971 Stravinsky

1910 1981 Barber

Monteverdi L'Orfeo 1607 First opera

Purcell Dido and Aeneas 1683

Handel Agrippina 1710

Handel Giulio Cesare 1724

Handel Theodora 1750

Gluck Orfeo ed Euridice 1762

Gluck Iphigenie en Tauride 1779

Mozart The Marriage of Figaro 1786

Mozart Don Giovanni 1787

Mozart The Magic Flute 1791

Beethoven Fidelio 1805

Rossini The Barber of Seville 1616

Rossini Othello 1816

Rossini The Thieving Magpie 1817

Rossini William Tell 1829

Wagner The Flying Dutchman 1843

Wagner Tannhauser 1845

Wagner Lohengrin 1850

Verdi Rigoletto 1851

Verdi The Troubadour 1853

Verdi La Traviata 1853

Offenbach Orpheus in the Underworld 1858

Berlioz Les Troyens 1858

Wagner Tristan and Isolde 1865

Verdi Don Carlos 1867

Wagner Das Rheingold 1869 Ring cycle 1

Wagner Die Walkure 1870 Ring cycle 2

Verdi Aida 1871

Strauss II Die Fledermaus 1874

Bizet Carmen 1875

Wagner Siegfried 1876 Ring cycle 3

Wagner Gotterdammerung 1876 Ring cycle 4

Saint-Saens Samson and Delilah 1877

Tchaikovsky Eugene Onegin 1879

Offenbach The Tales of Hoffman 1881

Wagner Parsifal 1882

Delibes Lakme 1883

Verdi Otello 1887

Humperdinck Hansel and Gretal 1893

Puccini La Boheme 1896

Puccini Tosca 1900

Debussy Pelleas et Melisande 1902

Puccini Madama Butterfly 1904

Strauss Salome 1905

Strauss Elektra 1909

Prokofiev The Love for Three Oranges 1921

Puccini Turandot 1926

Britten Peter Grimes 1945

Bernstein Candide 1956

Williams Star Wars IV 1977

Williams Star Wars V 1980

Williams Raiders of the Lost Ark 1981

Williams Star Wars VI 1983

Williams Star Wars I 1999

Williams Star Wars II 2002

Williams Star Wars III 2005

Williams Star Wars VII 2015

Williams The Sorcerer's Stone 2001

Williams The Prisoner of Azkaban 2004

Goldsmith The Shadow 1994

Goldsmith Alien 1979

Goldsmith Star Trek I 1979

Goldsmith Star Trek V 1989

Goldsmith Total Recall 1990

Goldsmith U.S. Marshals 1998

Horner Star Trek II 1982

Horner Star Trek III 1984

Horner Aliens 1986

Horner Glory 1989

Horner Braveheart 1995

Horner Apollo 13 1995

Horner Titanic 1997

Horner Troy 2004

Horner Avatar 2009

Horner The Amazing Spider-Man 2012

Zimmer The Lion King 1994

Zimmer Crimson Tide 1995

Zimmer The Rock 1996

Zimmer Mission Impossible II 2000

Zimmer Gladiator 2000

Zimmer Pearl Harbor 2001

Zimmer Hannibal 2001

Zimmer Curse of the Black Pearl 2003

Zimmer Batman Begins 2005

Zimmer Dead Man's Chest 2006

Zimmer The Da Vinci Code 2006

Zimmer At World's End 2007

Zimmer The Dark Knight 2008

Zimmer Angels and Demons 2009

Zimmer Sherlock Holmes 2009

Zimmer Inception 2010

Zimmer On Stranger Tides 2011

Zimmer Game of Shadows 2011

Zimmer The Dark Knight Rises 2012

Zimmer Man of Steel 2013

Zimmer The Amazing Spider-Man 2 2014

Zimmer Age of Extinction 2014

Zimmer Interstellar 2014

Zimmer Batman vs. Superman 2016

Kamen X-Men 2000

Davis The Matrix 1999

Doyle Thor 2011

Doyle The Goblet of Fire 2005

-2500 An ensemble of lyres was played in the ancient city of Ur, including

lyres, harps, flutes, and reed instruments.

1000 Bowed instruments first developed, such as the Lyre

1200 The guitar comes into use in Europe

1555 Amati develops the four-string violin

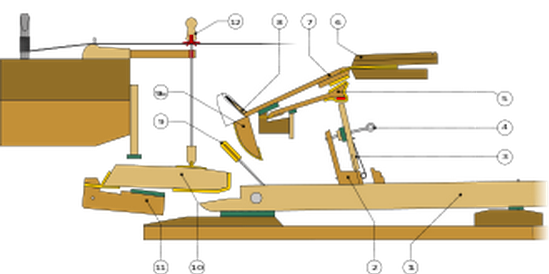

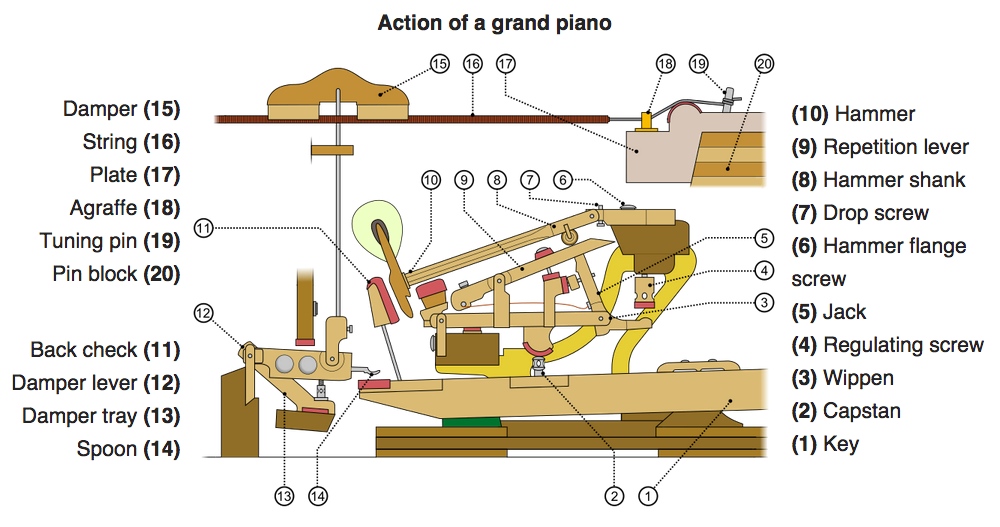

1700 Cristofori develops the first piano, an instrument where the string is

struck by a hammer. Early pianos had 5 octaves

1785 Tourte develops the modern bow

1810 Broadwood develops a 6-octave piano

1820 Broadwood develops a 7-octave piano

1821 Erard develops the double-escapement mechanism for the piano, a

device that permitted repeating a note even if the key had not yet risen

to its maximum vertical position. This facilitated rapid playing

of repeated notes.

1835 Tuba invented

1847 Boehm advances the design of the flute, including a switch from wood to metal

1931 Beauchamp builds the first electric guitar

A harpshichord string is plucked and a piano string is hammered.

A harpsichord can't vary its volume.

Invented the opthalmascope, an instrument for examining the inside of the eye.

This violin, now at the Metropolitan Museum of Art, may have been part

of a set made for the marriage of Philip II of Spain to Elisabeth of Valois in

1559, which would make it one of the earliest known violins in existence.

P = Pressure

T = Temperature

Vol= Volume

N = Number of gas molecules within the volume

k = Boltzmann constant

= 1.38*10^-23 Joules/Kelvin

Ideal gas law: (derivation)

P Vol = k T N

If we replace N with Moles then we obtain the form used in chemistry.

N = Moles * 6.62*10^23 (Avogadro's number)

P Vol = 8.3 Moles T

History of the discovery of gas laws:

1660 Boyle law P Vol = Constant at fixed T

1802 Charles law T Vol = Constant at fixed P

1802 Gay-Lussac law T P = Constant at fixed Vol

1811 Avogadro law Vol / N = Constant at fixed T and P

1834 Clapeyron law P Vol / T = Constant combined ideal gas law

M = Mass of a gas molecule

Vthermal= Characteristic thermal speed of gas molecules

E = Mean kinetic energy of a gas molecule

= 1/2 M V^2

Density = N M / Vol

e = Kinetic energy per volume

= N E / Vol

For a system in thermodynamic equilibrium each degree of freedom has

a mean energy of .5 k T.

E = 1.5 k T = .5 M Vthermal^2

The ideal gas law can be written in the form

P Vol = (1/3) N M Vthermal^2

P = (1/3) Density Vthermal^2

Gas simulation at phet.colorado.edu

Sound speed = ( Gamma * Pressure / Density )^{1/2}

where Gamma is the adiabatic constant, equal to 7/5 for air.

This is because diatomic molecules such as nitrogen and oxygen

have an adiabatic constant of 7/5.

Sound speed = ( Gamma Vthermal^2 / 3 )^{1/2}

= .68 Vthermal

The sound speed is proportional to the thermal speed of gas molecules.

Pressure / Density = k T / M

The sound speed is

Sound speed = ( Gamma * Pressure / Density )^{1/2}

= ( Gamma k T / M )^{1/2}

For air, sound speed depends only on temperature.

M in atomic mass units

Helium atom 4

Neon atom 20

Nitrogen molecule 28

Oxygen molecule 32

Argon atom 40

Krypton atom 84

Xenon atom 131

A helium atom has a smaller mass than a nitrogen molecule and hence has a

higher sound speed. This is why the pitch of your voice increases if you

inhale helium. Inhaling xenon makes you sound like Darth Vader.

1635 Gassendi measures the speed of sound to be 478 m/s with 25% error.

1660 Viviani and Borelli produce the first accurate measurement of the speed of

sound, giving a value of 350 m/s.

1660 Hooke's law published. The force on a spring is proportional to the change

in length.

1662 Boyle discovers that for air at fixed temperature,

Pressure * Volume = Constant

1687 Newton publishes the Principia Mathematica, which contains the first analytic

calculation of the speed of sound. The calculated value was 290 m/s.

Newton's calculation was correct if one assumes that a gas behaves like Boyle's

law and Hooke's law.

Because of Hooke's law, springs oscillate with a constant frequency.

X = Displacement of a spring

V = Velocity of the spring

A = Acceleration of the spring

F = Force on the spring

M = Spring mass

Q = Spring constant

q = (K/M)^(1/2)

t = time

T = Spring oscillation period

Hooke's law and Newton's law:

F = - Q X = M A

A = - (Q/M) X = - q^2 X

This equation is solved with

X = sin(q t)

V = q cos(q t)

A = -q^2 sin(q t) = - q^2 X

The oscillation period of the spring is

T = 2 Pi / q

= 2 Pi (M/Q)^(1/2)

According to Boyle's law, a gas functions like a spring and hence a gas oscillates

like a spring. An oscillation in a gas is a sound wave.

For a gas,

P = Pressure

dP = Change in pressure

Vol = Volume

dVol= Change in volume

If you change the volume of a gas according to Boyle's law,

P Vol = Constant

P dVol + Vol dP = 0

dP = - (P/Vol) dVol

The change in pressure is proportional to the change in volume.

This is equivalent to Hooke's law, where pressure takes the role of force

and the change in volume takes the role of displacement of the spring.

This is the mechanism behind sound waves.

In Boyle's law, the change in volume is assumed to be slow so the gas

has time to equilibrate temperature with its surroundings. In this case

the temperature is constant as the volume changes and the change is

"isothermal".

P Vol = Constant

If the change in volume is fast then the walls do work on the molecules,

changing their temperature. If there isn't enough time to equilibrate

temperature with the surroundings then the change is "adiabatic". You can see

this in action with the "Gas" simulation at phet.colorado.edu.

Moving the wall changes the thermal speed of molecules and hence the temperature.

If a gas consists of pointlike particles then

Vol = Volume of the gas

Ek = Total kinetic energy of gas molecules within the volume

E = Total energy of gas molecules within the volume

= Kinetic energy plus the energy from molecular rotation and vibration

dE = Change in energy as the volume changes

P = Pressure

dP = Change in pressure as the volume changes

D = Density

C = Speed of sound in the gas

d = Number of degrees of freedom of a gas molecule

= 3 for a monotomic gas such as Helium

= 5 for a diatomic gas such as nitrogen

G = Adiabatic constant

= 1 + 2/d

= 5/3 for a monatomic gas

= 7/5 for a diatomic gas

k = Boltzmann constant

T = Temperature

The ideal gas law is

P Vol = (2/3) Ek (Derived in www.jaymaron.com/gas/gas.html)

This law is equivalent to the formula that appears in chemistry.

P Vol = Moles R T

For a gas in thermal equilibrium each degree of freedom has a mean energy of

.5 k T. For a gas of pointlike particles (monotomic) there are three degrees of

freedom, one each for motion in the X, Y, and Z direction. In this case d=3.

The mean kinetic energy of each gas molecule is 3 * (.5 k T).

The total mean energy of each gas molecule is also 3 * (.5 k T).

Ek = 3 * (.5 k T)

E = d * (.5 k T)

Ek = (3/d) E

If you change the volume of a gas adiabatically, the walls change the kinetic and

rotational energy of the gas molecules.

dE = -P dVol

The ideal gas law in terms of E instead of Ek is

P Vol = (2/d) E

dP = (2/d) (dE/Vol - E dVol/Vol^2)

= (2/d) [-P dVol/Vol - (d/2) P dVol/Vol]

= -(1+2/d) P dVol/Vol

= - G P dVol/Vol

This equation determines the speed of sound in a gas.

C^2 = G P / D

For air,

P = 1.01e5 Newtons/meter^2

D = 1.2 kg/meter^3

Newton assumed G=1 from Boyle's law and calculated the speed of sound in air to be

C = 290 m/s

The correct value for air is G=7/5, which gives a sound speed of

C = 343 m/s

which is in accord with the measurement.

For a gas, G can be measured by measuring the sound speed. The results are

Helium 5/3 Monatomic molecule

Argon 5/3 Monatonic molecule

Air 7/5 4/5 Nitrogen and 1/5 Oxygen

Oxygen 7/5 Diatomic molecule

Nitrogen 7/5 Diatomic molecule

The fact that G is not equal to 1 was the first solid evidence for the

existence of atoms and it also contained a clue for quantum mechanics. If a

gas is a continuum (like Hooke's law) it has G=1 and if it consists of

pointlike particles (monatonic) it has G=5/3. This explains helium and argon

but not nitrogen and oxygen. Nitrogen and oxygen are diatomic molecules and

their rotational degrees of freedom change Gamma.

Kinetic degrees Rotational degrees Gamma

of freedom of freedom

Monatonic gas 3 0 5/3

Diatomic gas T < 1000 K 3 2 7/5

Diatomic gas, T > 1000 K 3 3 4/3

Quantum mechanics freezes out one of the rotation modes at low temperature.

Without quantum mechanics, diatomic molecules would have Gamma=4/3 at room

temperature.

E = Energy

dE = Change in energy

e = Energy density

Vol= Volume

P = Pressure

The volume expands as the universe expands.

dE = - P dVol

For dark energy, the energy density "e" is constant in space and so

dE = e dVol

Hence,

P = - e

Dark energy has a negative pressure, which means that it behaves differently

from a continuum and from particles.